Iron – a meaningful material

The most energy intensive part of iron production is the reduction process in which iron ore is reduced and therewith loses its oxygen content. Iron is processed further into various products used in our daily activities, such as cars and buildings.

Every year 1.9 billion tonnes of iron are produced globally, two thirds of which originate from primary production, i.e., the extraction of iron ore, whereas one third used recycled materials.

Iron production currently relies entirely on fossil fuels. As a result, the iron industry accounts for approximately 8% of annual global Greenhouse Gas emissions, making it one of the most significant drivers of climate change. As society is on the path towards global net zero emissions – which is needed to avert the worst impacts of climate change – the iron industry therefore faces significant challenges. On the flip side, the industry also has the unique opportunity to make impactful contributions to combat climate change while future-proofing iron production processes.

Not only regulators and investors demand a transition towards more environmentally friendly produced iron: Increasingly, customers all over the world recognize the impacts of their purchasing decisions, rapidly growing the demand for sustainable products.

The demand for iron is projected to increase to 2.2 billion tonnes/year by 2030, implying an annual increase of 50 million tonnes. Green iron production helps to meet this demand while taking responsibility for future generations and contributing to a healthy, sustainable planet.

Who we are?

HyIron was established through a partnership of Namibian and German companies that work in the field of renewable energies and engineering. At its heart is the HyIron technology, an innovative process to reduce iron ore in a rotary kiln with the help of green hydrogen, thus entirely carbon neutral. Every tonne of iron produced this way replaces 1.8 tonnes of CO2 in the traditional process!

At HyIron our aim is to implement and rapidly scale the production of green iron. Net zero industrial manufacturing of iron is, already today, economically competitive with positive environmental and economic impacts throughout the value chain.

How it works

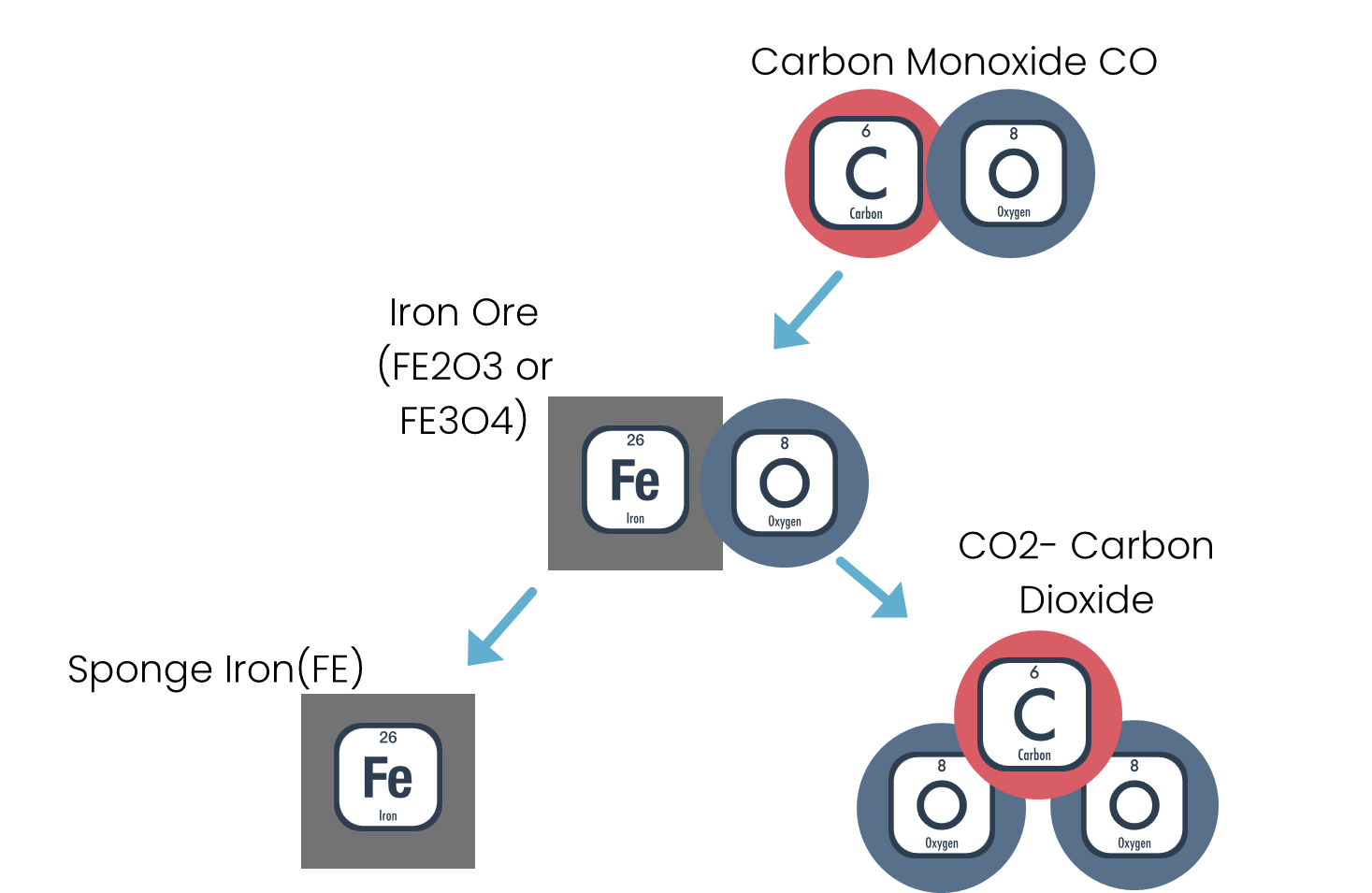

Iron ore is an oxide that needs to be reduced by separating it from its oxygen content before it is further manufactured into steel or cast iron. For this process, a reduction agent is required which draws the oxygen from the iron ore. Currently, fossil hydrocarbons such as coking coals are the most commonly used reduction agents. At HyIron we replace these hydrocarbons with green Hydrogen (i.e., entirely based on renewable energies) to produce a product called Direct Reduced Iron (DRI), which again is briquetted into Hot or Cold Briquetted Iron (HBI or CBI) – at zero emissions!

This product can then directly be used in foundries or steel factories to find its way into our daily life as steel or cast iron.

Classic process with carbon

Hydrogen as a new reducing agent

The project GEiSt (German for “Green Iron for the steel Industry”) pilots the technology in Lingen, Germany, in cooperation with RWE and Benteler. The main purpose of the pilot plant is to optimize the process and test various iron ores and to optimize the products used throughout the value chain. It has a maximum production capacity of 500 kg per hour and will be operational in Q1 – 2023. Read more…

The Oshivela (Oshivambo for Iron) project in Namibia will be the first application of the HyIron technology at an industrial scale with an anticipated launch in late 2024. At an initial output of 15.000 tonnes per year, the plant will demonstrate that industrial scale green iron production is economically and technically feasible. Due to a modular construction model, production can easily be scaled up to significantly larger outputs. Read more…

Planning a

successful build

Get your

design right

Get a building

consent

Complete

your project

We project manage the entire design and construction process

Preliminary planning, design, and engineering involving scope, and schedule to execute the construction on time and in control.

Give your home the best first impression with a structure that is attractive, efficient, and safe for years to come. Elevate your living space with an exceptional interior that balances beauty, utility, and value.

Being the Pioneer, Building the Future

Knowledgeable professionals

Laborum non occaecat aliquip officia et pariatur irure reprehenderit fugiat lorem magna aliqua proident. Labore ut ipsum commodo in proident eiusmod ut fugiat cillum velit est. Incididunt incididunt exte quis ad in esse labore. Anim tempor pariatur culpa et aliquip qui do proident eiusmod incididunt quis pariatur ea proident. Eiusmod esse aute cupidatat ad Lorem qui aute veniam deserunt laboris.

Pre-Construction and Planning

Knowledgeable professionals

Laborum non occaecat aliquip officia et pariatur irure reprehenderit fugiat lorem magna aliqua proident. Labore ut ipsum commodo in proident eiusmod ut fugiat cillum velit est. Incididunt incididunt exte quis ad in esse labore. Anim tempor pariatur culpa et aliquip qui do proident eiusmod incididunt quis pariatur ea proident. Eiusmod esse aute cupidatat ad Lorem qui aute veniam deserunt laboris.

We perform post-construction

Knowledgeable professionals

Laborum non occaecat aliquip officia et pariatur irure reprehenderit fugiat lorem magna aliqua proident. Labore ut ipsum commodo in proident eiusmod ut fugiat cillum velit est. Incididunt incididunt exte quis ad in esse labore. Anim tempor pariatur culpa et aliquip qui do proident eiusmod incididunt quis pariatur ea proident. Eiusmod esse aute cupidatat ad Lorem qui aute veniam deserunt laboris.

Learn more about our current projects.

Send us a message

To send us a message, please use the following form.

Contact us

Here you will find us. And if you have any questions or ideas you want to share, contact us.